XM Wire Rope Hoist System

The XM wire rope hoist system from Misia is full of features and quality components which can be arranged in a number of different configurations in order to suit particular lifting operations.

These powerful lifting hoists can be foot mounted (suspended or supported), monorail mounted, (standard or low headroom) or bi-rail mounted (crab unit).

The XM Wire Rope Hoist System

Manufactured in Italy with top quality components the range of Misia wire rope hoists offer a configurable electric hoisting system to suit many industrial environments. With the highest working load limit topping out at 50 tonne there will almost certainly be a model to suit your lifting needs.

The XM Electric Wire Rope Hoist Models.

Lifting Hoists Direct can supply four various models as standard which you will find all the details for here and in the specifications above. However special applications can also be catered for on request.

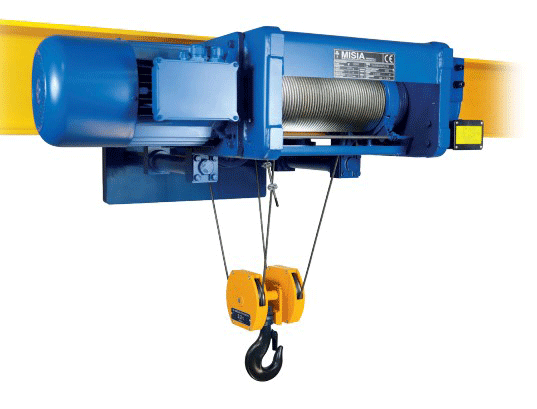

The Standard Headroom Monorail Hoist

This set up is available in working load limits ranging from 1000kg to 16000kg on 2 rope falls(S2) and 2000kg up to 32000kg on 4 rope falls(S4).

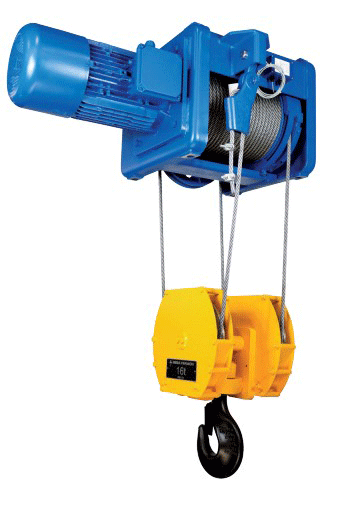

The Low Headroom Monorail Hoist

With this version of the XM hoist is 2 rope falls are chosen the WLL ranges from 1000kg to 5000kg (S2) or if 4 rope falls are chosen the range is from 2000kg to 10000kg(S4).

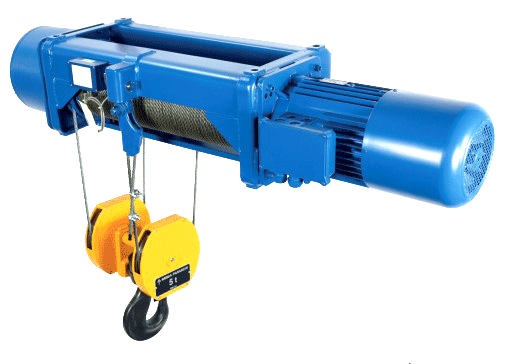

The Foot Mounted Monorail Hoist

The working load limits for the foot mounted XM hoist will depend on whether is is suspended from or supported by the beam. For 2 rope falls the WLL ranges from 1000kg to 25000kg for both suspension types. With 4 rope falls the range is from 2000kg up to 50000kg for supported fitting but only up to 25000kg for suspended set ups.

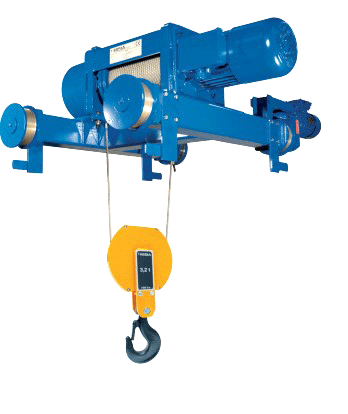

The Bi-rail Hoist (crab unit)

1000kg to 25000kg is the WLL range on a 2 fall hoist (S2); Whilst 2000kg up to 50000kg is the WLL on a 4 fall hoist (S4).

Please refer to the specifications for more technical details and dimensions.

Key Components

No matter which configuration you choose there are many similarities between each model.

The Gearbox

For example the gearboxes are the same across the XM range, they are lifetime lubricated, and are the planetary type with 2 or 3 stages. Gears are made from heat treated, quality steel.

Because the gearbox is of the planetary type the motor speed is reduced according to the needed RPM of the drum.

The Motors

There are two types of motors which can be used with the full range of Misia XM electric rope hoists.

In the specifications you will find options for a cylindrical motor and a conical motor.

With a cylindrical motor the rotor is perfectly cylindrical and together with the disc brake you have the choice of a single or dual speed version. The motor is 3-phase and asynchronous.

A conical motor has a conical rotor as well a a conical brake. There is a helical spring to actuate the brake system. Axial displacement of the rotor (turning power on) causes the brake to release.

The Rope Guide

The rope guide has two components and is responsible for guiding the rope so that the correct position of the rope is maintained. The two parts are a guide ring and a pressure spring. The spring ensures the rope lays correctly into the drum grooves whilst the ring maintains the correct position and prevents the rope slipping off the drum groove.

The Load Limiter

There are overload limiters on each 2 and 4 fall hoist which have two reaction thresholds for optimum performance. The limiter works by acting on the auxiliary circuit, first by activating a warning then secondly by stopping all movement, both lifting and travel actions. Once the second level is engaged the only possible action is lowering a load.

The Trolleys

There are three common types of trolley systems for the Misia XM wire rope hoist. The standard headroom monorail for operation directly under and parallel with the crane/runway beam. Suspension is via a drive trolley.

Next comes the Low headroom monorail trolley system which has two motors on planetary gearboxes which are fitted directly onto the wheel’s drive shaft.

Lastly there is the bi-rail trolley system or crab unit. Designed to be either suspended or supported. With the hoist suspended below. Incorporating 4 dual edge wheels with bearings. Two drive wheels connect directly to the gear motor which is self braking.

Get in touch if you need any more information. Or check out our other powered lifting hoists such as electric hoists, scaffold hoists or air hoists.

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online