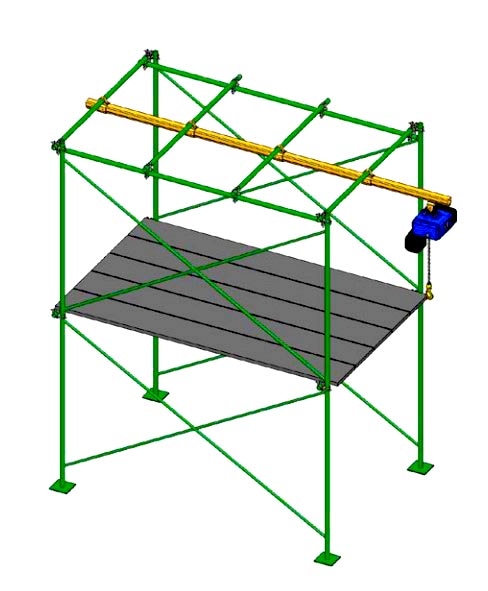

Scaffold Runway Crane System

This scaffold runway crane system is designed specifically for attaching to scaffolding in order to provide a runway crane across the span of the scaffolding and beyond. This fully customizable system enables lifting loads to the height required and moving them along the runway beam to the loads final destination.

Scaffold Runway Crane System Specifics

A scaffold crane system with a runway beam has a lot more to offer than a standard scaffold hoist. Not only can these systems lift your load up the side of a build they also enable the load to be traversed/moved across the runway to the precise location where it is needed. Therefore when you have a heavy or awkward load it can be taken directly to where it is required rather than just to the required level/height like a scaffold hoist alone.

Installing and Customizing the Scaffold Crane

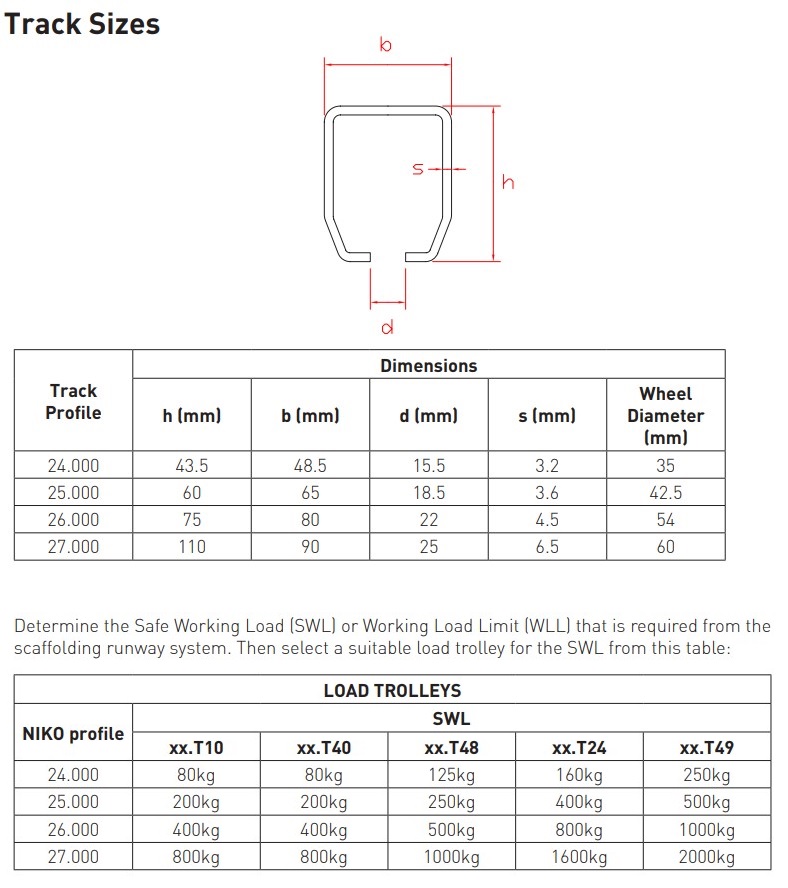

Customisable to suit your scaffolding tower the runway beams come in 3 or 6 metre lengths as standard with a choice of beam connectors, clamps for scaffold attachments and trolley systems for your hoist. End stops are an essential part as these prevent trolleys and hoists from running off the beam. Runway track profile sizes range from 24 to 27 and the system can handle loads ranging from 100kg up to 2000kg.

You will find that the clamps are dual purpose, they clamp the runway beam using pinch bolts whilst also fixing securely to the scaffolding using the scaffold clamp with securing bolt. There are a number of trolley options to choose from to suit your lifting applications and range from a standard trolley with anchor hole/eye or a rotating eye to a double load trolley system. (see images).

The scaffold runway crane system is fairly easy to install thanks to the wide range of individual components, meaning that it can be installed section by section by a couple of competent people.

The specifications tables show the basic track sizes but can often be further customized on request. More detailed information can be found in the Document download above.

Please get in touch if you require any guidance with designing your ideal scaffold crane.

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online