Although the Lifting Hoists Direct website predominantly deals with lifting hoists we can also supply a great selection of associated lifting equipment to compliment our range of hoists.

Certain types of lifting hoists will benefit from some additional lifting equipment. For example, say you have an electric hoist, how would you attach it to a gantry beam? With a beam trolley of course! Another example would be how do you attach a load to a hoist’s hook? A lifting sling would be useful here!

There are many other scenarios where associated equipment will be required in order to successfully complete a lifting application.

Choose from Lifting Shackles – Lifting Slings – Eye Bolts and Lifting Clamps

Associated Lifting Equipment Available

We have put together a few popular essentials which you can purchase at the same time as your hoist.

Beam Trolley

A beam trolley enables you to anchor a hoist to the beam of a crane. The trolley simply clamps onto the flanges of a steel beam. They are easy to adjust and tighten with the central screw pin which also incorporates the lifting eye where your hoist is fitted. The big benefit of our beam trolley offering is that is can be manually pushed across the beam, hoist, load and all. So if you need to lift AND move a load then our Delta beam trolley could be right up your street. Its keenly priced, reliable and robust.

Beam trolleys clamp onto a steel beam so that hoisting equipment can be attached and moved across the beam.

There are 3 main types of trolleys, push travel, geared and powered and although we can supply all kinds (just ask!) here we are offering the type most commonly used when associated with lifting hoists – the push travel trolley.

Push Travel Beam Trolley

As the name suggests this type of trolley is manually pushed along the beam. They are generally chosen for their simplistic design, ease of use and minimal maintenance. They are also usually the cheapest option out of all the trolley types. Once fitted correctly to a beam the wheels on the trolley will run along the flange smoothly. Your chosen hoist is attached to the incorporated central eye suspension point on the trolley. Once a load is attached to the hoist the whole lot can be pushed along to where you need it. Pushing the trolley along is typically carried out by pushing on the load, hoist or hoist load hook. You must however ensure the load remains stable and secure.

Lifting Hoists Direct are offering the Delta push trolley at low cost prices. They are robust and easy to fit to a range of beam widths thank to the adjustability. They also come in a range of working load limits with the highest spec model boasting 5000kg.

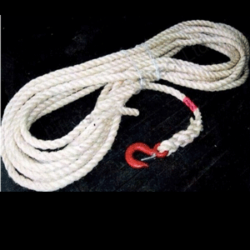

Lifting Slings

There are different types of lifting slings that are great for using with hoists. We can supply webbing slings, round slings and chain slings to suit your requirements. We can supply web slings with safe working loads up to 10000kg, round slings up to 12000kg and chain slings up to 31 tonne. The chain slings are in grade 8 steel and come in a choice of single leg, double leg, 3 leg of 4 leg configurations.

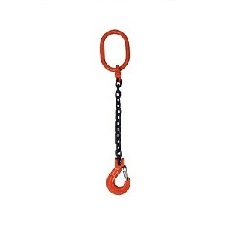

Lifting with Chain Slings

Chain slings are particularly versatile and can be used in a variety of ways thanks to the wide range of designs available.

A chain sling may have just one length of chain with a master link at one end and typically a safety load hook on the other, this is known as a single leg chain sling. Multiple leg chain slings are also commonly used. They come in double leg, 3 leg and 4 leg chain slings with each leg connecting into the top masterlink.

The chain can be almost any length, they can be used in different hitch types and even have one or more leg temporarily shortened with a shortening clutch. Go to the chain sling page below to find out more.

Web Slings for Lifting Tasks

Web slings are made from densely woven high tensile polyester material. They are incredibly strong and loads up to 10 tonne can be lifted with our standard range.

A web sling may be seen as a simplex web sling or Duplex web sling. A simplex sling is made from a single layer of material whereas a duplex has 2 layers and is therefore much stronger and our prefferred type.

This type of sling can come in a wide array of lengths to suit your needs. They are a single length of material with a soft eye loop at each end, typically reinforced with a wear sleeve for added protection. Vertical, choke and basket type hitches can be used with a webbing sling and so can be used successfully for a range of load types and sizes.

Round Lifting Slings

Round lifting slings are similar to web slings in that they are a type of lifting strap made from high strength polyester. However a round sling is manufactured quite differently. They are made into seemless tubes and filled with a high tensile fibre core.

The fibre core gives this sling its strength; up to 12 tonnes comes as standard from our range. The outer polyester tubular cover protects the core and provides additional strength. All hitch types can be used with a round sling. Round slings are much softer and are perfect for more delicate loads.

Choosing and Using Lifting Slings

When deciding on the type of lifting sling you need you need to take into account certain specifics. What is your lifting medium? (i.e. electric hoist) how heavy is your load? Do you need to pick up your load in a particular way? What type of load is it? If you are not sure then get in touch and ask a member of our team who will be happy to steer you in the right direction.

When using lifting slings you should adopt safe slinging practices, potentially undergoing training. There are many do's and don'ts to consider when using slings and these rules may change between the different types so please make sure you are up to date with the Safe use of information leaflets by the LEEA. These can be found on the associated product pages.

Lifting Clamps

Sometimes a lifting clamp is preferable to a sling when handling particular loads especially large flat ones. Also you may need to lift sheet type objects horizontally or vertically which used to mean two types of clamps. Not with the Delta universal plate lifting clamp. This can lift in either orientation thanks to the hinged lifting eye.

Lifting clamps come in many formats with each suited to lifting specific loads. For example plate lifting clamps are designed to handle plate materials such as steel sheets.Clamps for lifting are a great accompaniment for hoisting equipment as they will enable you to lift, lower and potentially turn products with relative ease. They can be used with electric hoists, chain blocks and air hoists as well as scaffold hoists and wire rope hoists.

The majority of lifting clamps will incorporate a lifting eye. This is the part that is used to attach the clamp to the load hook on a hoist.

Plate lifting clamps are a popular piece of lifting equipment, especially in the steel industry. The typical types enable either horizontal lifting or vertical lifting but not both. However in more recent years universal plate clamps have become more commonplace due to the fact that they can do both.

It is the specially designed hinged lifting eye which enables them to lift in both vertical and horizontal orientations. The other bonus with this type is that you can pick up a sheet vertically and set it down horizontally. And visa versa should you need to, all thanks to the pivotal hinge. Angled lifting is also permissible providing the reduced safe working load according to the lifting angle is adhered to.

Plate clamps can be used individually but are typically used in pairs or more, especially for larger sheet materials. The more clamps used the more secure the lift will be.

How Plate Lifting Clamps Work

Plate lifting clamps are really quite simple in design. They incorporate an opening jaw within a steel casing. The jaw is opened up to insert the sheet material, the grooves/teeth on the jaw will help to hold the load securely, however the load will not be fully secure until it is lifted. This is because the clamps use the forces implied by the weight of the load to clamp tightly. Thus as a load is lifted the jaws will clamp tighter and tighter progressively as the weight implies more force onto the jaw clamping it tighter.

At the moment we are offering the Delta Universal plate lifting clamp with safe working loads up to 2 tonne as standard, however we are also able to supply up to 5 tonne.

Please see the product below to find out all the details.

Lifting Shackles

Shackles offer a semi permanent means of connecting items together. For example the two eyes of a lifting sling can be brought together and secured with a shackle prior to attaching to a hoist. We can supply most types of shackles but here you will find the most popular ones used in lifting applications. Large dee and large bow shackles can be found as well as alloy green pin bow and dee shackles.

When you need to connect certain types of lifting equipment together the most popular product to use is a lifting shackle. They come in a variety of designs to suit different scenarios. Although we can supply any type of shackle the ones you find here are our best sellers. Ideal for use with electric hoists, chain blocks, wire rope winches or any other type of hoist.Lifting Shackles for Hoisting Tasks

The equipment used in a typical lifting application will vary somewhat, however the structure of the task will be similar. For example the load needs to be harnessed then connected to hoist's load hook; the hoist is typically fitted to a beam trolley on a gantry crane beam.

Therefore the layout could be;

Load--sling--shackle--load hook--hoist--trolley--gantry crane. Obviously this is just a simple format of which there are many, but it gives you an idea.

Lifting slings must always sit in the saddle, NEVER on the pin.

About Lifting Shackles

A Lifting shackle essentially gives you a temporary means of connecting two or more items such as joining the two eyes on a web sling.

They are temporary thanks to the screw pin method of securing the shackle. The screw pin simple screws in and out of the saddle. They are a quick and efficient connection method with installation and removal completed in seconds. These should be checked regularly to ensure then do not come loose.

If you would like something even safer then consider a shackle with a safety bolt which are considered as a semi-permanent connection. They have a pin just the same but with a screw nut to make the pin more secure. Additionally on the other side of the nut a cotter pin is inserted. This ensures the nut and subsequently the pin can not come loose.

They may take a little longer to install and remove, however they can be left in place for long periods if required. Still check regularly though to ensure all is good. A bad connection can result in the failure of the lift with potentially nasty consequences.

Shackle Types

Shackles come in two main shapes and are called 'D' or Dee and Bow shackles.

They are used for different types of lifting applications so make sure you choose the right one.

D Shackle Basics

D shackles have a saddle with straight sides and a rounded bowl and have the same internal measurement from pin to bowl. This type of shackle is intended to be used for straight lifts only. Where the load's centre, and shackle are vertically in line with the hoist's load hook and thus the centre of gravity.

Bow Shackle Basics

A bow shackle has a saddle with a bowl shape. It s internal dimensions are wider at the bowl than near the pin. Because of their more rounded shape they are able to be used at an angle without compromising the safety of the connection. There will, however be a reduction to the safe working load. (see the bow shackle page for more)

Lifting Hoists Direct has picked out 4 popular shackles for use with our other equipment. They include large Dee and Bow shackles as well as green pin, safety bolt types for both 'D' and bow shackles. If you need something else that you can't find here then pick up the phone and call 01384 76961, we can usually supply for all your lifting equipment needs. From beam trolleys, slings and lifting clamps to the exemplary collection of hoisting equipment including the latest Delta electric hoist.

Buying your Lifting Equipment

Whilst some products are available to purchase online, some are not! However it is really easy to order all the equipment you need in one go with a quick phone call to the sales team. Our helpful team will be happy to offer advise, give you a quote with the most up to date prices, take your order and payment and advise on delivery times. 01384 76961 is the number to call, alternatively you can drop us an email with your requirements.

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online