Large D Shackles

£2.51 – £69.75

There is a choice of two types of large d shackles available for lifting and hoisting applications. One has a standard type screw pin and the other has a safety bolt. The latter comes in higher lifting capacities up to 11.25 tonne whilst the screw pin shackle goes up to 9.5 tonne.

About Large D shackles

Due to their ‘D’ shape these large lifting shackles should only be used for vertical lifts. Slings should sit neatly in the saddle, never on the pin. They are ideal for connecting loads to a hoist or crane hook.

Forged from high tensile quality steel we supply these large dee shackles in their self coloured finish. However we are able to supply them with a hot dipped galvanised finish on request should you require this option.

These robust shackles boast a 5:1 safety factor which means they have a breaking load minimum strength of five times the stated working load limit. That said you should never exceed the stated load limit stamped on the shackle. The safety factor is there to provide the upmost safety allowing for any errors in unidentified load weights. This is not ideal, nor recommended. You should always know the true weight of your load, using a crane scale or load cell if necessary.

The standard starting point for load capacities for both types of large d shackle is half a tonne (0.5t). From there you will find many increments until the upper limit as stated above is reached. As you go up the scale the dimensions of the shackle will increase. So whilst taking into account your required lifting capacity you will also need to be sure that the dimensions also meet your needs.

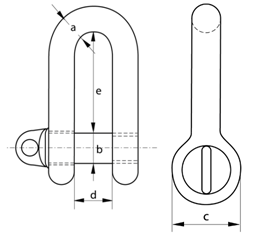

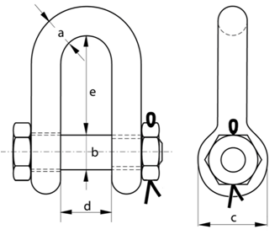

Consult the specifications to find out the measurements of the bow, pin and eye diameters as well as lengths and widths. The weight of each shackle is also there so this can be calculated into the total load weight.

Screw Pin Vs Safety Bolt Shackle

Screw pin shackles are pretty standard. They are best used in applications where he shackle needs to be removed and reconnected frequently as they are quck and easy to install.

The pin slides in through the holes at the bottom of the saddle where it screws into place to secure it. Depending on the lifting application and frequency it it sometimes possible for this type to loosen or worst case, the pin comes right out. This is often due to vibrations, twisting and other movements that take place during the lifting operation. For this reason you should frequently check the screw pin is tight.

Safety bolt shackles are much safer in terms of coming out, they cant! They are ideal for more permanent or semi-permanent connections as they are a little more fiddly to install and remove.

Just like on a standard screw type, the pin slides through the saddle, however it is slightly longer and protrudes out the other side. This is where the nut in fitted and secured with a split pin / cotter pin. Once in place it is unlikely it will come out on its own accord, incidentally you will likely need pliers to remove the cotter pin in order to disconnect the shackle.

More shackles for hoisting jobs

When you are using hoisting equipment such as electric hoists or manual chain blocks you will typically see some type of lifting sling and shackle for anchoring the load. Lifting Hoists Direct specialise in hoisting equipment but also supply the most commonly used associated lifting equipment for this type of application. From green pin shackles, clamps, slings and trolleys you can get all your lifting gear right here. Can’t find what you aare looking for? No problem, call the team on 01384 76961 and let them know your needs, we can usually help.

| Weight | N/A |

|---|---|

| Capacity (shackle) | 0.15 Tons, 0.45 Tons, 0.50 Tons, 0.75 Tons, 1.25 Tons, 1.5 Tons, 2 Tons, 2.75 Tons, 3 Tons, 3.75 Tons, 4.75 Tons, 5 Tons, 5.75 Tons, 6 Tons, 7 Tons, 7.25 Tons, 8.5 Tons, 9.5 Tons |

| Pin Type Required (shackle) | Screw Pin, Safety Bolt |

PDF DOWNLOADS

safe use of lifting shackles PDF

SPECIFICATIONS

| Working Load Limit | Diameter Bow | Diameter Pin | Diameter Eye | Inside Width | Inside Length | Weight Each |

| tons | a inch | b inch | c inch | d inch | e inch | kg |

| 0.25 | ¼ | 3/8 | ¾ | ½ | 1 | 0.06 |

| 0.5 | 3/8 | ½ | 1 | ¾ | 1.1/2 | 0.16 |

| 0.75 | ½ | 5/8 | 1.1/4 | 1.1/8 | 2.1/8 | 0.35 |

| 1.5 | 5/8 | ¾ | 1.1/2 | 1.1/4 | 2.1/2 | 0.63 |

| 2 | ¾ | 7/8 | 1.3/4 | 1.1/2 | 2.7/8 | 1 |

| 3 | 7/8 | 1 | 2 | 1.3/4 | 3.1/4 | 1.54 |

| 3.75 | 1 | 1.1/8 | 2.1/4 | 2 | 3.3/4 | 2.21 |

| 5 | 1.1/8 | 1.1/4 | 2.1/2 | 2.1/8 | 4.1/8 | 3.11 |

| 6 | 1.1/4 | 1.3/8 | 2.3/4 | 2.3/8 | 4.1/2 | 4.33 |

| 7 | 1.3/8 | 1.1/2 | 3 | 2.5/8 | 5 | 5.33 |

| 9.5 | 1.1/2 | 1.3/4 | 3.1/2 | 2.3/4 | 5.3/8 | 8.46 |

| 11.25 | 1.5/8 | 1.7/8 | 3.3/4 | 3 | 5.3/4 | 10.48 |

| 13 | 1.3/4 | 2 | 4 | 3.1/4 | 6.1/8 | 12.66 |

| 14.25 | 1.7/8 | 2.1/8 | 4.1/4 | 3.5/8 | 7 | 15.34 |

| 16.25 | 2 | 2.1/4 | 4.1/2 | 3.7/8 | 7.3/8 | 18.5 |

| 18 | 2.1/8 | 2.3/8 | 4.3/4 | 4.1/8 | 7.3/4 | 23.8 |

| 20 | 2.1/4 | 2.1/2 | 5 | 4.1/4 | 8.1/4 | 28.6 |

Large D Shackle with Safety Bolt

| Working Load Limit | Diameter Bow | Diameter Pin | Diameter Eye | Inside Width | Inside Length | Weight Each |

| tons | a inch | b inch | c inch | d inch | e inch | kg |

| 0.25 | ¼ | 3/8 | ¾ | ½ | 1 | 0.1 |

| 0.5 | 3/8 | ½ | 1 | ¾ | 1.1/2 | 0.2 |

| 0.75 | ½ | 5/8 | 1.1/4 | 1.1/8 | 2.1/8 | 0.5 |

| 1.5 | 5/8 | ¾ | 1.1/2 | 1.1/4 | 2.1/2 | 0.68 |

| 2 | ¾ | 7/8 | 1.3/4 | 1.1/2 | 2.7/8 | 1.3 |

| 3 | 7/8 | 1 | 2 | 1.3/4 | 3.1/4 | 1.8 |

| 3.75 | 1 | 1.1/8 | 2.1/4 | 2 | 3.3/4 | 2.8 |

| 5 | 1.1/8 | 1.1/4 | 2.1/2 | 2.1/8 | 4.1/8 | 3.68 |

| 6 | 1.1/4 | 1.3/8 | 2.3/4 | 2.3/8 | 4.1/2 | 4.92 |

| 7 | 1.3/8 | 1.1/2 | 3 | 2.5/8 | 5 | 6 |

| 9.5 | 1.1/2 | 1.3/4 | 3.1/2 | 2.3/4 | 5.3/8 | 9.5 |

| 11.25 | 1.5/8 | 1.7/8 | 3.3/4 | 3 | 5.3/4 | 11.56 |

| 13 | 1.3/4 | 2 | 4 | 3.1/4 | 6.1/8 | 14.92 |

| 14.25 | 1.7/8 | 2.1/8 | 4.1/4 | 3.5/8 | 7 | 16.36 |

| 16.25 | 2 | 2.1/4 | 4.1/2 | 3.7/8 | 7.3/8 | 19.88 |

| 18 | 2.1/8 | 2.3/8 | 4.3/4 | 4.1/8 | 7.3/4 | 25.22 |

| 20 | 2.1/4 | 2.1/2 | 5 | 4.1/4 | 8.1/4 | 29.86 |

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online