SSC4 Subsea Chain Block – William Hacketts

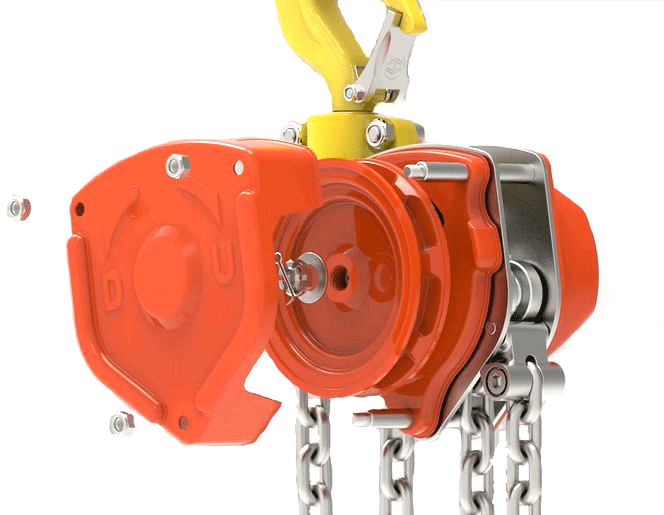

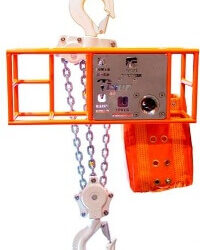

With high corrosion resistance and quad pawls the SSC4 subsea chain block is ideal for use in offshore and marine applications as well as water treatment facilities. Available in working load limits up to a huge 50 tonne.

SSC4 Subsea Chain Block Key Features

Made and tested in the United Kingdom here are some key features at a glance;

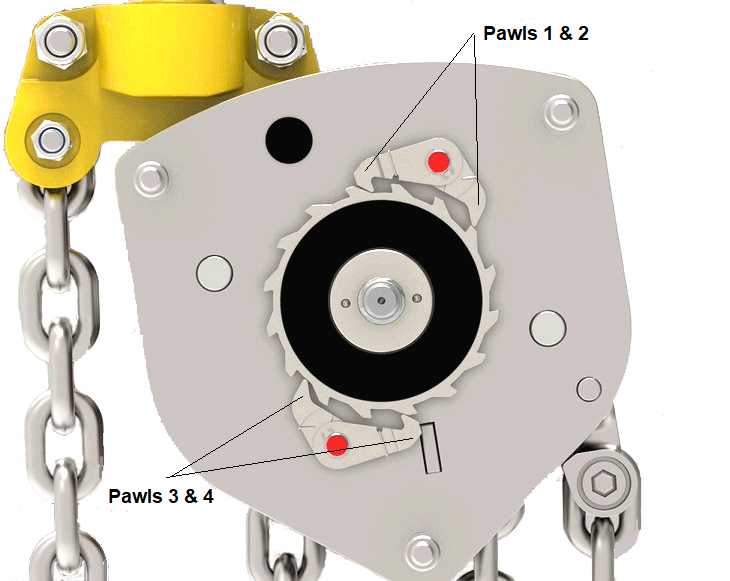

- Quad pawls

- light load capabilities

- corrosion protection

- Specialised marine paint finish

- high performance grease

- stainless steel fixings

- safety latches on hooks

- Hook overload markings with traceability

- hand chain joiner

- fleeting allowed to 45 degrees

- overload limiter on request

Hacketts Subsea Chain Block Design

With an offset configuration of the ratchet gear, all four mechanical pawls will engage as the gear turns. Because there are 4 there will always be at least one pawl engaged at all times offering optimum safety. Additionally the patented quad pawl system enables more precise adjustments and thus better tensioning capabilities. The pawl set up has undergone testing to twice the industry norm.

Another good safety feature is the hook and latch system. The heavy duty cast steel catches integrate with the hook tip on closure, thus creating a very secure connection point. The hooks also incorporate indicator markings so its easy to check is they have been overloaded. Traceability codes are also included on both hooks.

Corrosion Resistance of the SSC4 Subsea Manual Chain Hoist

When it comes to the corrosion resistance of the Hacketts SSC4 subsea chain block there are a number of specific components and coatings for optimum protection in wet conditions.

Firstly all pawl circlips, internal springs, nyloc nuts and socket head screws are all stainless steel for high protection properties.

Secondly all major components have additional protection from corrosion, these include; brake, pinion shaft, disc hub, gears, pawls, pawl stands and sheaves. Chain guide, stripper and stay bolts are also protected. The highest quality grease is used throughout the hoist,

For the finishing coating category 5 marine paint is utilised in triple layers. The paint is to ISO12944 standards and suitable for high corrosive conditions, typically with a 7-15 year life span.

Hoist Immersion Specifics

Due to the nature in which these hoists are used there are a number of specific criteria which must be adhered to. It is essential to read all information and manuals to ensure all specifics are met.

The subsea chain block can be used fully immersed for up to 21 days at a time or up to 31 days for multiple immersions. After this period of use the hoist must be thoroughly serviced by an authorised agent with a complete strip down for full inspection. Rigorous load testing should also be carried out. Data logs must be kept.

It is important flush out the hoist with clean water (unpressurised) after each submersion period, prior to storing. This will help to protect the hoist and thus prolong its life.

We have included the user manual for download above for the full details.

More Subsea Hoisting Solutions

Our subsea hoisting category incorporates a number of manual hoists that can be used offshore and subsea under specific conditions. Both lever hoists and chain blocks can be found as well as ROV suitable set ups.

Get in touch with the Lifting Hoists Direct Team if you need any help.

PDF DOWNLOADS

SSC4 Subsea Chain Block Information Flyer

SSC4 Subsea Chain Block Manual

Specifications

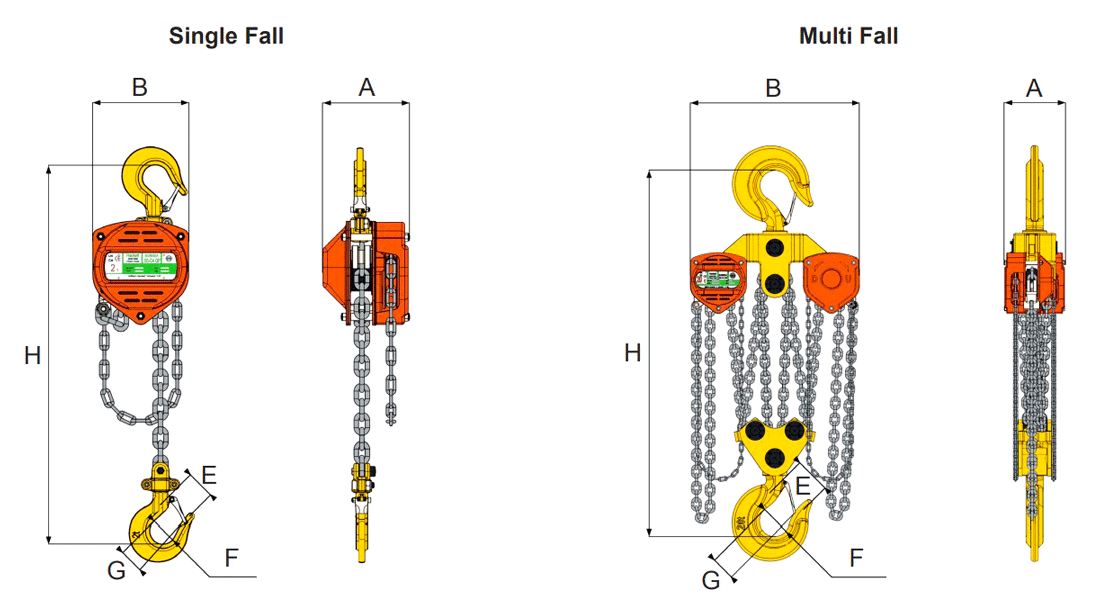

| Part Code | WLL tonnes | No. of Falls | Load Chain mm | Hand Chain mm | Standard Lift m | Dimensions | Mass kg 3m HOL | Extra Weight per m kg | |||||

| A mm | B mm | E mm | F mm | G mm | H min mm | ||||||||

| 025.SS.053 | 0.5 | 1 | 6 x 18 | 5 x 25 | 3 | 134 | 155 | 49 | 40 | 25.5 | 350 | 11.1 | 1.7 |

| 025.SS.103 | 1 | 1 | 6 x 18 | 5 x 25 | 3 | 134 | 155 | 49 | 40 | 25.5 | 350 | 11.1 | 1.7 |

| 025.SS.163 | 1.6 | 1 | 8 x 24 | 5 x 25 | 3 | 157 | 185 | 51.5 | 40 | 30 | 390 | 16.8 | 2.2 |

| 025.SS.203 | 2 | 1 | 8 x 24 | 5 x 25 | 3 | 157 | 185 | 54.5 | 44 | 30 | 410 | 16.8 | 2.2 |

| 025.SS.32D3 | 3.2 | 2 | 8 x 24 | 5 x 25 | 3 | 157 | 235 | 61 | 48 | 37.5 | 495 | 24.2 | 3.6 |

| 025.SS.503 | 5 | 2 | 10 x 30 | 5 x 25 | 3 | 180 | 262 | 85 | 60 | 43 | 635 | 38.4 | 5.2 |

| 025.SS.753 | 7.5 | 3 | 10 x 30 | 5 x 25 | 3 | 180 | 373 | 89 | 83 | 53 | 775 | 58.2 | 7.5 |

| 025.SS/1003 | 10 | 4 | 10 x 30 | 5 x 25 | 3 | 180 | 406 | 89 | 83 | 53 | 815 | 68.9 | 9.6 |

| 025.SS/1503 | 15 | 6 | 10 x 30 | 5 x 25 | 3 | 210 | 406 | - | 108 | 80 | 1000 | 116.7 | 13.9 |

| 025.SS/2003 | 20 | 8 | 10 x 30 | 5 x 25 | 3 | 225 | 550 | - | 108 | 80 | 1100 | 149.5 | 19.2 |

| 025.SS/3003 | 30 | 12 | 10 x 30 | 5 x 25 | 3 | 460 | 800 | - | 140 | 112.0* | 1550 | 515 | 27.9 |

| 025.SS/5003 | 50 | 20 | 10 x 30 | 5 x 25 | 3 | 580 | 840 | - | 180 | 140.0* | 2000 | 750 | 45.2 |

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online