Stagemaker SR Entertainment Hoist

The Stagemaker SR Entertainment Hoist has been innovatively designed with all the latest technology.

Stagemaker SR Entertainment Hoist

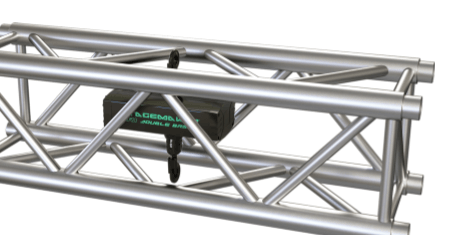

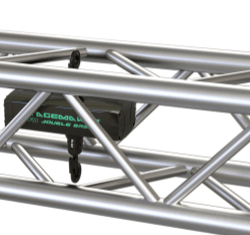

One of the biggest benefits of Stagemaker SR entertainment hoist is that it can be used in two different configurations. The standard industrial position with the main body upwards. In this configuration the load attaches to the lower hook and is raised and lowered on the chain with the main body remaining stationary. In the second configuration the main body of the hoist is in a downward position (upside down). This is often called a climbing hoist. The hoist is mounted/anchored with its load chain and the hoist body / hook attaches to the load. Therefore the whole body of the hoist is raised and lowered along with the load. Climbing hoists are often easier for installation purposes.

Another key benefit to using a Verlinde Stagemaker SR entertainment hoist is the safety aspect. These hoists incorporate an unprecedented double lifting brake system as standard to ensure the load is always held. What’s more the position of the clutch, which is in the reducer, ensures the brake stays engaged, guaranteeing the load is always held firm.

Innovative components of the Stagemaker SR Entertainment Hoist

The SR entertainment hoist incorporates no less than three new innovative components.

The ‘perfect push’ greatly improves chain flow. It also reduces the risk of the chain becoming jammed. The 5 pocket load wheel with five intermediate teeth are responsible for this chain movement.

The ‘chain flux’ is made in aluminium for high strength. It allows the chain to flow smoothly into the chain bag whilst reducing jamming risks. It also enables horizontal flow as the chain comes off the load wheel. The chain flux design also incorporates a drainage system to minimise water collection within the load wheel area.

The ‘Limit flux’ is basically a limit switch. On this model it has been built into the chainflux. This enables greater control and precision when setting the hoist in any configuration. The limit switch operates via an upper and lower magnetic ring which is easy to move along the chain.

Ergonomics & operating convenience

The streamlined, ergonomically improved design of Stagemaker hoists along with their robust stature and high end technology, makes them perfect for use within the entertainment industry. Being powder coated in black epoxy paint they perform very well in more extreme temperatures (-20 to +50 degrees c). They integrate well into theatre rigging operations.

The gripping surface of the lifting hook is ergonomically designed and rubber coated. The rubber coated hand grips enable easier handling. With the operating sound level down to just 60db it is quieter than other hoists.

Maintenance of the SR stage hoist is relatively simple. With easy access to fuses, torque limiter and plug & play electric boards. Visual access to the brake system for control and an easy to dismount motor further enhance the ease of maintenance. A chaining tool is included along with a high grade, removable chain container. Remember to follow the PLASA entertainment guidelines.

Versions of the Stagemaker SR Entertainment Hoist

The SR stage hoist is available in 2 variations. Version A with 3 phase and direct voltage control. Version B is a 3 phase hoist with low voltage control. Please refer to the technical specifications tab to view the details. Here you will also find detailed information on each of the 12 models available. They have lifting capacities ranging from 125kg up to 5000kg.

There are other complimentary products available as shown on the main Stagemaker Hoist page (view here) including, cases, load cells, 3 types of controllers (eco; rigger & theatre) and cable guides.

Stagemaker Hoists Accessories

Alongside the Stagemaker chain hoist we can also supply a range of Stagemaker accessories to include a large range of flight type cases for easy transportation and storage. There are force gauges and/or load cells for load calculations. We can supply cabling and push button controllers as well as complete control panel systems.

large range of flight type cases for easy transportation and storage. There are force gauges and/or load cells for load calculations. We can supply cabling and push button controllers as well as complete control panel systems.

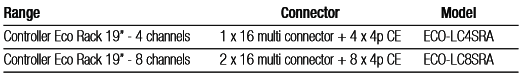

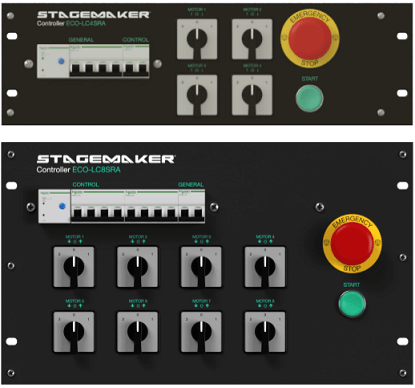

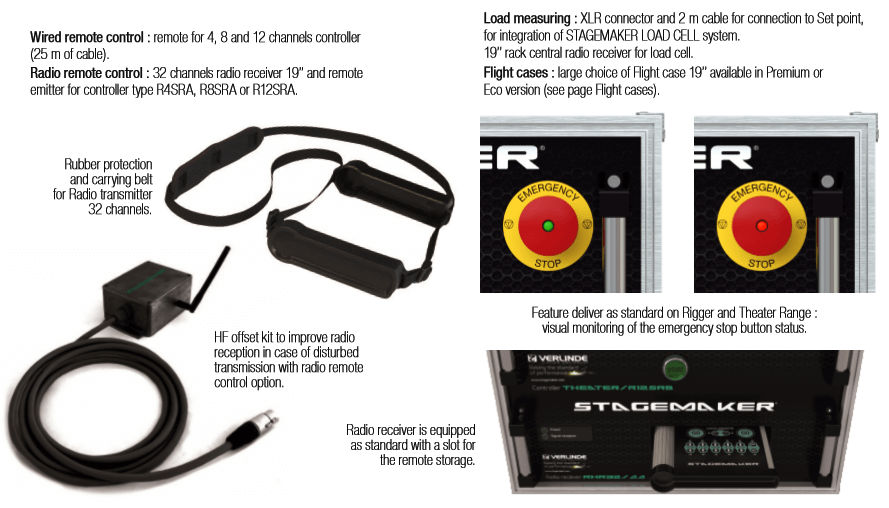

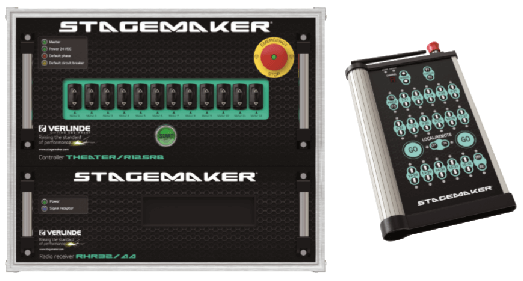

Stagemaker hoists controllers come with 4 or 8 channels. Therefore enabling hoist control individually or in groups. Approved by official EU institutes, the controller conforms to all European electrical safety standards (IEC & EMC). Additionally there is a range of controllers which can be used with the SM series.

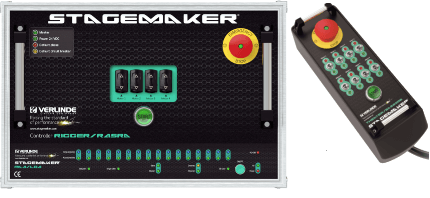

The R8 allows CPU connection to up to 8 units. Therefore enabling the pre-programming of the hoist or hoists to specific locations and heights and at specific times. What’s more the hoist or group of hoist can be stopped immediately from the controller with the emergency stop switch.

Controller Packs

Three controller packs are available, the Eco, the Rigger & the Theatre;

Firstly the Eco pack is probably the most economical. It consists of a steel case (4 or 8 channels) with  direct control. Indicator lamp for phase monitoring. Multi connect outputs (for each group of 4 motors) power & control.

direct control. Indicator lamp for phase monitoring. Multi connect outputs (for each group of 4 motors) power & control.

Short circuit protection, thermal protection and a 32 A 5p CE power-in plug. The maximum power per channel is 1,8kW / 400v 3 Ph. Flight cases available.

Secondly the Rigger control pack has a four channel direct control with a radio receiver for a radio load cell  and a wired remote control unit. Key features include: phase detection with auto correct feature.

and a wired remote control unit. Key features include: phase detection with auto correct feature.

Cabling for possible wired or wireless remote controller as standard. Standard master/slave function, multi connect output. Short circuit protection 1,8w /400 v 3 Ph maximum power per channel.

Other Rigger Options:

Thirdly the Theatre Controller Pack is designed for the version ‘B’ range of Stagemaker chain hoist systems for lower voltage controls. There are 12 channels, a central receiver and radio emitter for remote controllers.

Master / slave functionality, power supply – 400/415 v 3Ph –N- 50/60Hz; phase detect & auto correct; cabling for possible remote control (wired or wireless)

Extra Options Available For the Theatre controller

Load Cell Options for the Stagemaker Entertainment Hoist Range.

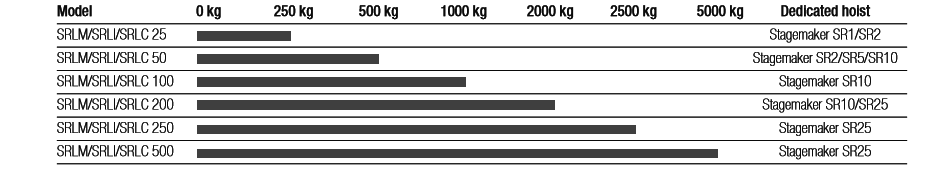

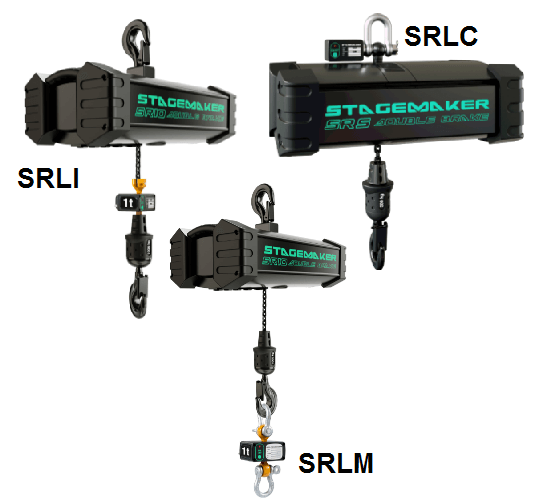

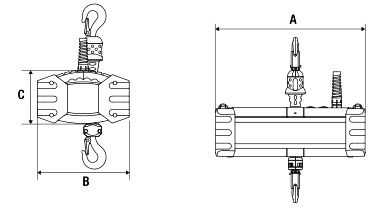

This is a specialised system for measuring the weight of the load a Stagemaker chain hoist is holding. Most importantly it also enables continual monitoring. They are totally wireless and each cell transmits with total independence. Because of the multiple channels available.

Consequently this ensures there is no cross contamination of information between different loadcells. There are 3 models. Firstly the SRLI is a radio integrated load cell, fixed to the load chain. Secondly the SLRM has shackles to fit between the hook and load. Finally the SRLC radio load cell is fixed to the top suspension hook.

Specifications

| Load capacity | BGV-D8 Model | BGV-D8+ Model | Hoist speed 50Hz (m/min) | Number of falls | Chain size Ø(mm) x pitch (mm) | Motor power (kW) | Weight (without chain) (KG) | Dimensions with 2 Brakes | ||

| A mm | B mm | C mm | ||||||||

| 125KG | SR1 124 m1 A | 4 | 1 | 4 x 11 | 0.25 | 10.4 | 344¹ | 153 | 100 | |

| SR5 1216 m1 A | 16 | 1 | 5 x 14 | 0.45 | 30.5 | 502³ | 280 | 164 | ||

| 160 kg | SR2 164 m2 A | 4 | 1 | 4 x 11 | 0.23 | 20.1 | 477² | 240 | 140 | |

| SR2 168 m2 A | 8 | 1 | 4 x 11 | 0.45 | 20.1 | 477² | 240 | 140 | ||

| 250KG | SR1 254m1 A | 4 | 1 | 4 x 11 | 0.19 | 10.4 | 344¹ | 153 | 100 | |

| SR1 252 m1 A | 2 | 2 | 4 x 11 | 0.19 | 10.4 | 344¹ | 153 | 100 | ||

| SR5 254 m2 A | 4 | 1 | 5 x 14 | 0.45 | 30.5 | 502³ | 280 | 164 | ||

| SR5 258 m2 A | 8 | 1 | 5 x 14 | 0.9 | 30.5 | 502³ | 280 | 164 | ||

| SR5 2516m1 A | 16 | 1 | 5 x 14 | 0.9 | 30.5 | 502³ | 280 | 164 | ||

| SR10 2516 m1 A | 16 | 1 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | ||

| 320 KG | SR2 324 m2 A | 4 | 1 | 4 x 11 | 0.23 | 20.1 | 477² | 240 | 140 | |

| SR2 328 m1 A | 8 | 1 | 4 x 11 | 0.45 | 20.1 | 477² | 240 | 140 | ||

| 500 KG | SR1 502 m1 A | 2 | 2 | 4 x 11 | 0.19 | 10.4 | 344¹ | 153 | 100 | |

| SR5 504 m1 A | 4 | 1 | 5 x 14 | 0.45 | 30.5 | 502³ | 280 | 164 | ||

| SR10 504 m2 A | 4 | 1 | 7 x 20 | 0.9 | 44.6 | 544? | 335 | 181 | ||

| SR5 508 m1 A | 8 | 1 | 5 x 14 | 0.9 | 30.5 | 502³ | 280 | 164 | ||

| SR10 508 m1 A | 8 | 1 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | ||

| SR10 516 m1 A | 16 | 1 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | ||

| 800 KG | SR10 804 m1 A | 4 | 2 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | |

| 1000 KG | SR10 1004 m2 A | 4 | 1 | 7 x 20 | 0.9 | 44.6 | 544? | 335 | 181 | |

| SR10 1004 m1 A | 4 | 2 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | ||

| SR10 1008 m1 A | 8 | 1 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | ||

| 1250 KG | SR25 1204 m1 A | 4 | 1 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | |

| SR25 1208 m1 A | 8 | 1 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | ||

| 1600 KG | SR10 1604 m1A | 4 | 2 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | |

| 2000 KG | SR10 2004 m1A | 4 | 2 | 7 x 20 | 1.8 | 44.6 | 544? | 335 | 181 | |

| 2500 KG | SR25 2504 m2 A | 4 | 1 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | |

| SR25 2504 m1A | 4 | 2 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | ||

| SR25 2508 m1A | 8 | 1 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | ||

| 5000 KG | SR25 5004 m2A | 4 | 2 | 11.3 x 31 | 3.6 | 98 | 649? | 393 | 205 | |

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online