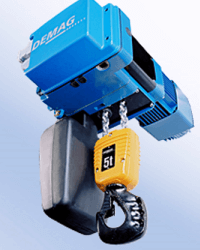

Wind Turbine Electric Hoists Demag DC Wind

Heights of up to 180 metres can be achieved with a Demag DC Wind turbine electric hoist, enabling equipment up to 1500kg to be transported efficiently into the Nacelle of the turbine for set up and maintenance tasks.

About Wind Turbine Electric Hoists

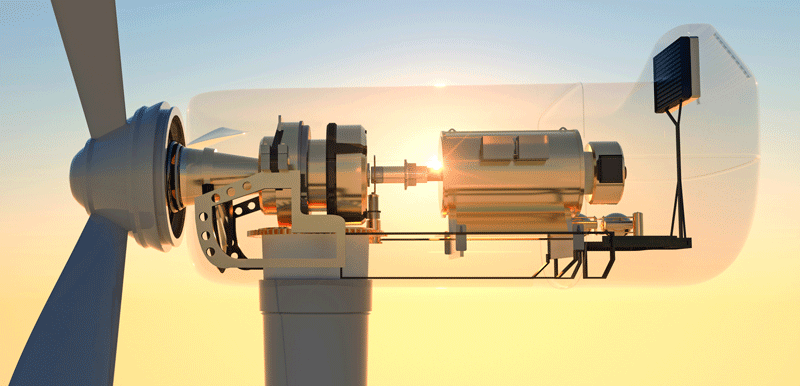

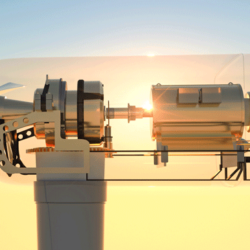

Wind turbines are coming more and more prevalent on our landscape due to being a more eco-friendly and sustainable source of energy. However wind turbines are huge and not so easy to reach when they require servicing and repairs.

If a turbine goes down then power generation stops so quick access is necessary to reduce down time.

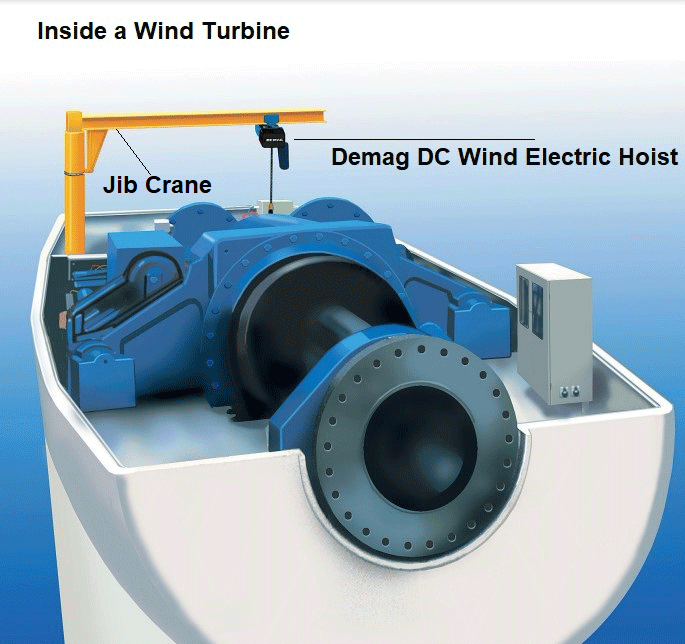

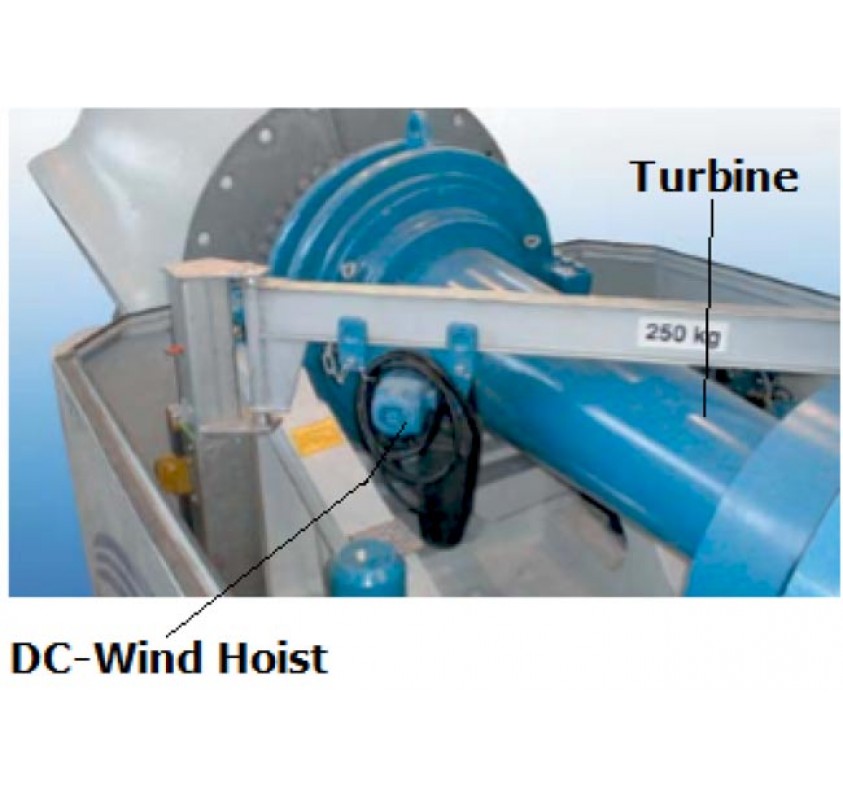

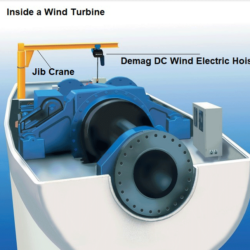

Specialist electric hoists for use on wind turbines such as the Demag DC-wind are typically used for both on and off shore turbines. They enable tools and equipment to be transported right up into the body of the turbine – the Nacelle.

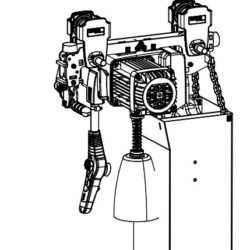

The hoist can be anchored inside the Nacelle body thanks to the low headroom design and are commonly fitted to a monorail type runway system so that the hoist can be moved around inside the Nacelle to aid in equipment handling in different areas.

The Demag DC Wind Turbine Electric Hoist Features

Designed to meet the stringent requirements of this industry the Demag DC Wind turbine electric hoist is frequently used around the globe thanks to its high safety specifications and reliability.

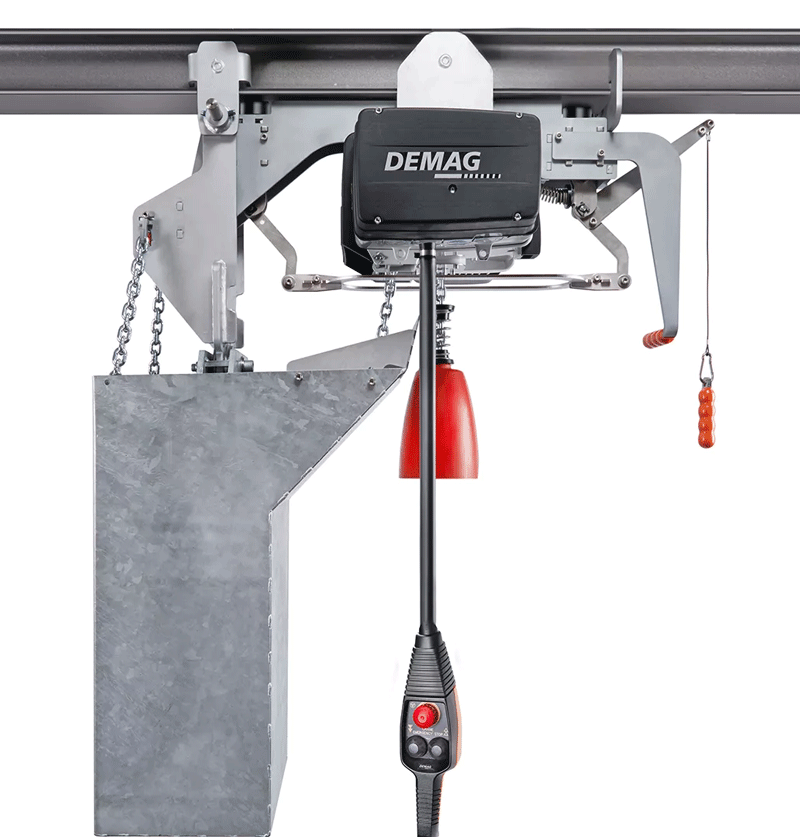

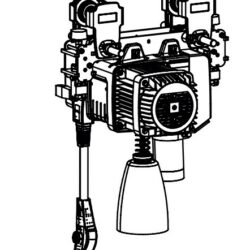

Installation is straight forward with plug and lift connections, the control cable can be quickly adjusted without re-wiring and excess chain is held in a suitable sheet metal chain collector box.

The DC wind turbine hoist boasts a maintenance free (up to 10 years) gearbox, slip clutch and brake system.

Fast lifting speeds up to 24 metres per minute means your equipment can be handled with the highest efficiency. Continuous and efficient operation at these vast lifting heights is down to the up to 100% cyclic duty factor motors.

Convenient operation for precision positioning due to the creep speed mode and with all the benefits of the other DC hoist models, as well as many optional extras to choose from, for example; higher installation heights, radio control, special corrosion protection and cold climate options.

Safety Aspects of the DC Wind Turbine Hoist

There are numerous safety components in this electric hoist as well as a number of optional extras for further enhancement. As standard the corrosion protected brake system with IP55 rated enclosure is positioned under and IP55 rated electrical equipment cover.

Limit switches for both top and bottom hooks improve safety whilst the chain collector keeps excess chain out of the way.

The trolley to which the hoist is fitted can be locked into place with a special locking device.

There is a brake-coupling system in place which guarantees the load will be held in any situation, thus prevents the load from dropping.

Special options include special designs for specific installations and weather conditions such as off shore operations, cold climate versions and high altitude applications.

More Information

If you need more information you can watch a short video here as well as find technical details in the specifications above. Please get in touch if you need more help.

| SWL (KG) | Type | LS at 50 Hz (m/min) | Hook path (H) | Trolleys with frame | Chain dimensions | >Max. weight *) KG | |

| RUDC | Stationary | ||||||

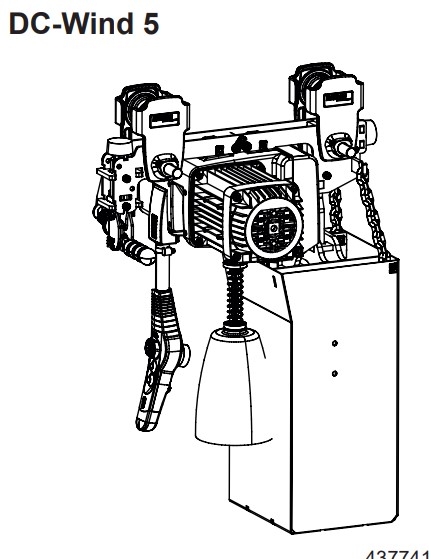

| 125 | DC-Wind 2 | 16/4 | ≤120 | 2 x RU 3/2 | 4.2 x 12.2 | 28 | 20 |

| 125 | DC-Wind 5 | 24/6 | 2 x RU 3/2 | 4.2 x 12.2 | 33 | 26 | |

| 250 | DC-Wind 5 | 16/4 | 2 x RU 3/2 | 4.2 x 12.2 | 33 | 26 | |

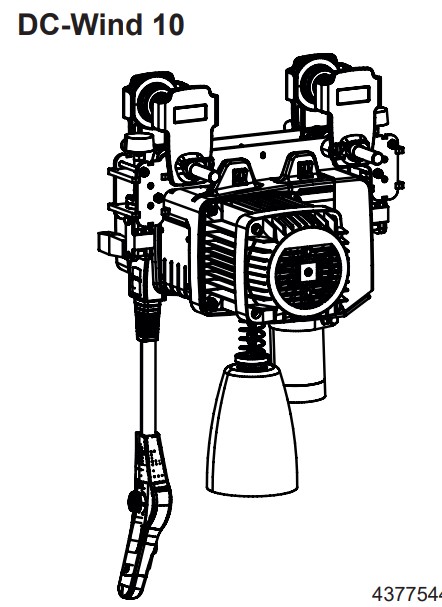

| 250 | DC-Wind 10 | 24/6 | ≤180 | 2 x RU 6/2 | 5.3 x 15.2 | 59 | 45 |

| 500 | DC-Wind 5 | 12/3 | ≤120 | 2 x RU 3/2 | 5.3 x 15.2 | 43 | 36 |

| 500 | DC-Wind 10 | 12/3 | ≤120 | 2 x RU 6/2 | 5.3 x 15.2 | 59 | 45 |

| 500 | 24/6 | ≤180 | 2 x RU 6/2 | 5.3 x 15.2 | 59 | 45 | |

| 800 | 18/4.5 | ≤150 | 2 x U 11 | 7.4 x 21.2 | 84 | 64 | |

| 1000 | 18/4.5 | ≤120 | 2 x U 11 | 7.4 x 21.2 | 84 | 64 | |

| 1000 | 12/3 | ≤120 | 2 x U 11 | 7.4 x 21.2 | 84 | 64 | |

| 1200 | DC-Wind 15 | 16/4 | ≤150 | 2 x U 11 | 8.7 x 24.2 | 155 | 125 |

| 1500 | 12/3 | ≤120 | 2 x U 11 | 8.7 x 24.2 | 155 | 125 | |

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online