Yale Low Headroom Chain Block and Trolley

The Yale low headroom chain block and trolley combination is available in working load limits up to 10000kg with a choice of push travel or geared trolley systems.

Yale Low Headroom Chain Block and Trolley Options

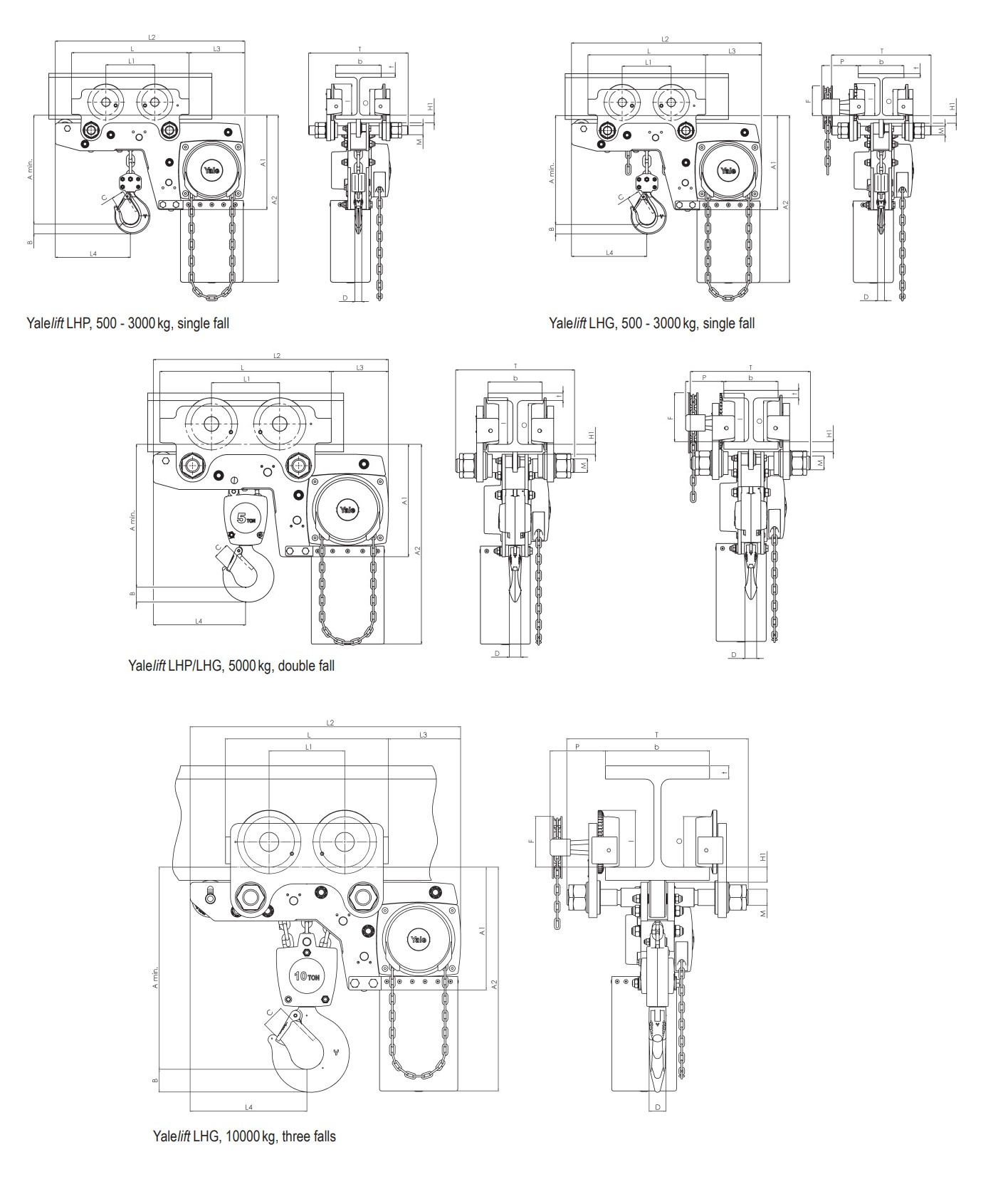

Using the Yale 360 chain block and a specially configured trolley system the bottom block/load hook to pass through a chain guide and reeving system laterally.

This set up enables the load hook and load to be lifted almost right up to the beam flange, thus making the most of the available lifting height.

When it comes to lifting capacity there are a few options ranging from 500kg up to 10000kg. All models up to the 3000kg version have one chain fall the higher capacities will have two or three, you can confirm this in the full specifications above.

Other Benefits

A further benefit to the Yale low headroom chain block and trolley system is the choice of trolley type and size. First of all there are two types of trolley which are the push travel trolley which is pushed along the beam manually, typically by pushing the bottom block and/or load. The geared travel trolley option moves across the beam by pulling on a chain, this passes over gears and subsequently propels the trolley forward or backwards depending on which chain is pulled.

Secondly there are two sizes of each trolley to ensure they fit most beam sizes. In the specifications you will see them labelled ‘A’ or ‘B’ The ‘A’ size trolleys typically fit smaller beam flange widths than the ‘B’ size. Size ‘A’ usually covers the majority of applications (about 80%) as they fit flanges up to 180mm.

The wheels on the integrated trolley systems have been designed with pre-lubricated ball bearings which are encapsulated and ensure consistent, smooth travel. They are designed for use on a maximum 14% beam profile incline (DIN 1025-pt.1)

Other features of the Yale low headroom chain block and trolley YLLH include anti-drop and tilt devices, ensuring your trolley always remains on the beam securely as it should. There is an almost step less system to adjust the trolley for quick and easy assembly and installation thanks to the adjustable nuts.

Further Enhancements to the YLLH Low Headroom Chain Block & Trolley

There are a few optional extras to consider to further enhance this low headroom hoisting system. At the top of the list will probably be the adjustable overload protection device, closely followed by a chain container. This combination is always popular.

Rubber buffers on the trolley and a beam locking device to secure an unloaded system in a fixed place on the beam are other options to consider.

This combination can also be supplied in a corrosion resistant version or an ATEX rated version. Please get in touch if you would like more information or quotes on these.

For other low headroom hoists take a look at the Liftket electric hoist low headroom set up or the Stahl ST electric hoist which is modular and can be set up in various ways.

PDF DOWNLOADS

Yale Low Headroom Chain Block and Trolley Information

Specifications

| Model | Capacity in kg/number of chain falls | Size | Beam flange width b (mm) | Beam flange thickness t max (mm) | Curve radius min (m) | Weight at standard lift (3m)-Push (KG) | Weight at standard lift (3m)-Geared (KG) | Weight at standard lift (3m) with locking device- Push (KG) | Weight at standard lift (3m) with locking device- Geared (KG) |

| YLLH 500 | 500/1 | A | 60-180 | 19 | 0.9 | 27 | 31 | 33 | 38 |

| YLLH 500 | 500/1 | B | 180-300 | 19 | 0.9 | 27 | 32 | 34 | 38 |

| YLLH 1000 | 1000/1 | A | 70-180 | 19 | 0.9 | 35 | 40 | 43 | 48 |

| YLLH 1000 | 1000/1 | B | 180-300 | 19 | 0.9 | 36 | 41 | 44 | 49 |

| YLLH 2000 | 2000/1 | A | 82-180 | 19 | 1.15 | 61 | 65 | 69 | 73 |

| YLLH 2000 | 2000/1 | B | 180-300 | 19 | 1.15 | 62 | 67 | 70 | 75 |

| YLLH 3000 | 3000/1 | A | 100-180 | 19 | 1.5 | 107 | 112 | 116 | 121 |

| YLLH 3000 | 3000/1 | B | 180-300 | 19 | 1.4 | 109 | 114 | 118 | 123 |

| YLLH 5000 | 5000/2 | A | 110-180 | 28 | 2 | 152 | 157 | 162 | 167 |

| YLLH 5000 | 5000/2 | B | 180-300 | 28 | 1.8 | 156 | 161 | 166 | 171 |

| YLLH 10000 | 10000/3 | A | 125-180 | 40 | 1.8 | On Request | 230 | On Request | On Request |

| YLLH 10000 | 10000/3 | B | 180-310 | 40 | 1.8 | On Request | 232 | On Request | On Request |

Dimensions

| Model | YLLH 500 | YLLH 1000 | YLLH 2000 | YLLH 3000 | YLLH 5000 | YLLH 10000 |

| A min, mm | 188 | 211 | 264 | 316 | 425 | 565 |

| A1,mm | 223 | 250 | 289 | 346 | 345 | 365 |

| A2,mm | 381 | 427 | 511 | 614 | 612 | 665 |

| B,mm | 17 | 22 | 30 | 38 | 45 | 68 |

| C,mm | 24 | 29 | 35 | 40 | 47 | 68 |

| D,mm | 14 | 19 | 22 | 30 | 37 | 50 |

| F (geared trolley), mm | 92 | 92 | 91 | 107 | 150 | 150 |

| H1,mm | 24 | 24 | 24 | 32 | 31 | 45 |

| I (pushed trolley), mm | 72 | 72 | 96 | 131 | 143 | 170 |

| I (geared trolley), mm | 77 | 77 | 98 | 133 | 149 | 170 |

| L,mm | 270 | 310 | 360 | 445 | 525 | 485 |

| L1,mm | 130 | 130 | 150 | 180 | 209 | 225 |

| L2,mm | 444 | 488 | 582 | 690 | 720 | 805 |

| L3,mm | 124 | 135 | 172 | 203 | 175 | 215 |

| L4,mm | 184 | 201 | 230 | 265 | 283 | 348 |

| M,mm | M18 | M22 | M27 | M30 | M42 | M48 |

| O,mm | 60 | 60 | 80 | 112 | 125 | 150 |

| P (geared trolley), mm | 108 | 110 | 112 | 112 | 117 | 165 |

| T (area A), mm | 280 | 290 | 305 | 320 | 364 | 440 |

| T (area B), mm | 400 | 410 | 425 | 440 | 484 | 540 |

Fast Delivery

Fast Delivery Low Prices

Low Prices Buy Online

Buy Online